By Alexander Pocock

Every dairy farmer knows the importance of keeping their milking parlour in tip-top condition. We don’t have to tell you that they need to be well-maintained, kept clean and monitored for any structural problems. However, when you’re milking a large herd multiple times a day, it can be quite easy to let standards slip. Just look at recent research which states that 70% of parlours have problems that reduce the quality of milk.

This is quite an overwhelming figure and one that must change. The important question is how? A dynamic parlour test provides the ideal opportunity, helping to take your milking parlour for a test drive. As a recommendation by Red Tractor, a dynamic test enables dairy farmers to quickly pinpoint issues and identify ways in which a parlour can be improved.

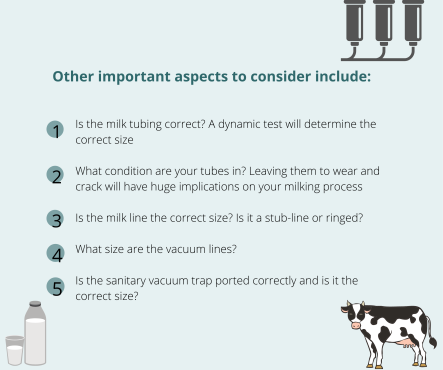

There is no specification on what this should include, with many tests only taking the baseline issues into consideration. Yet, to carry out the task properly, it requires much broader thinking and analysis. A lot of factors must come into play in order to keep your parlour at its best.

So, what should you look for when advising on dynamic testing?

The journey doesn’t just start at the parlour

Issues stemming from poor health can cost farmers time and money to fix, not to mention milk quality and quantity can be compromised. It is, therefore, best practice to adopt a rigorous process that evaluates the whole milking journey.

The process starts in the collecting yard, and then on to the parlour. There needs to be consideration into the design and size, and whether both are suitable for cattle. Is there rubber matting in the parlour and what condition is it in? How clean are the clusters and standings? What is the attitude of the milker? Are they wearing gloves? Evaluate the entry and exit of the parlour, including where the cows go after milking. Answering these questions is paramount to the safety of your cattle and, in turn, a successful milking round.

Making the most of the milking parlour

When it comes to a dynamic test, one vital factor to mention is the teats; are they in good condition? Or are they rough, ringed and damaged? If problems do occur, you need to understand why.

An element that could possibly have an effect on a cow’s teats is how efficiently the clusters are applied. Are the teats clean, dry and well stimulated prior to cluster attachment? Is the positioning correct? This is just one aspect of the preparation routine, with timings, chemicals used, and coverage all vital points to consider.

Speaking of clusters, this is a part that cannot be forgotten. Is your cluster unit the correct size for the lactation of the cows? Are they flooding at peak let down? A prep-lag time of 60-90 seconds between stimulation and attachment is necessary for optimum milk-let down. Once finished, are the clusters being removed cleanly? These are all essential questions to ask if you want to see improvements. Yes, they may seem like minor factors, but all could have an enormous impact on efficiency and costings in the long run.

Your vacuum will hugely impact milk flow, so make sure it isn’t unstable due to poor regulator control, inadequate vacuum reserve or poor layout. Is the regulator fitted correctly? Is the VOD (vacuum on demand) sensor in the correct place? Is the regulator the correct size and capacity for the size of the plant?

Seeing the complete picture

The post-milking routine is just as important as the one carried out before milking. When undertaking a dynamic milk test, it is the concluding factor that will help to provide a complete picture of the process. You must go back to the teats and examine if they’re wet with milk when the cluster has been removed. The conditions the teats are in must also be reviewed. Are they showing signs of stress? Is the lining protruding out the end of the teat? Are there rings around them?

ADF (automatic dipping and flushing) systems, dip cups and teat sprayers are an essential part of the process. The post milking disinfection gives protection to the teat end after milking when the teat orifice is still open.

Other questions to ask when a cow exits include, do they face any restrictions when leaving? Are there sharp turns/step downs or narrow passages to contend? Can they leave without causing congestion? Although the milking is done, there is still a requirement to ensure the cattle are kept safely and that they’re stress-levels remain low.

What can we do to help?

Some people think dynamic testing is only about testing the milking system at the cluster when the cows are being miked. It should do this, but there is much more to it. While it may appear an overwhelming task, carrying out a thorough dynamic test is fundamental for the future of your dairy farm. Not only is it an essential step towards improving the quality of milk, it’s crucial for maintaining high welfare and health standards. The milking specialists at Genus are on hand to undertake a full Dynamic Milking Time Test, providing insight into your milking machine, cattle and operators.

Email farmdirect@genusplc.com or call 01270 616816 for a quote.

For further guidance on cow comfort and how to create the best conditions for your cattle, get in touch with our farming consultancy team. They’re on hand to help you make informed decisions about caring for your dairy cows.